Buyer beware: Procuring Information with Confidence

The essential role of information management capability and capacity assessment, and a guide to implementation

When you procure products or services, you’re not only buying ‘the thing’ but in most cases you’re also purchasing information or data. This could be:

Product information:

Technical data

Manufacture data

Logistics data

Service information:

Schedule and associated data

Quality data

Reporting data

I’ve been in the construction industry for 17 years with involvement in dozens of tenders and projects. The breakdown between expectation and delivery of information has been a consistent thorn in the side of successful delivery. The pain comes in the form of extra work, increased costs, delay, and stress.

You start with the best intentions…

We all want to make things more efficient and flowing when it comes to delivering our projects. In the beginning you have a clear picture. You know how your systems and processes are going to be integrated and how this effort is going to save our time, money, and sanity. You build your processes as lean as possible, and you make your platforms and systems work seamlessly to support these processes. You even go to the effort to identify all of the information and data you need to make the processes flow and truly optimise. You build an integrated project delivery system - removing data silos, re-using information where ever possible, and maximising the value of the resources at your disposal.

Perfect, but…

You can’t deliver the project alone, as with any construction project, you need a wider delivery team. You need designers, subcontractors, and suppliers. So, you get your information requirements, standards, and procedures tied into appointment, agreements and contracts. Great move.

Unfortunately, once you get going, things start to go off-course. Your information flows aren’t functioning how you planned. The processes seem clunky. There seems to be a lot of effort in something that should be running lean. It becomes clear that some of your delivery team can’t deliver what they’ve signed up to.

You take steps to understand. Turns out they really needed this work - they get so much information in enquiry packs - they can’t possibly read it all…

You have need to spend time sorting out the issues, bring in more resources to support the supply chain, cave on a few requirements, and employ a BIM agency to carry out some modelling work on behalf of some suppliers…

Costs have gone up, programme is slipping. You’re dealing with issues you thought you’d solved - adding stress and work to your already full plate. This isn’t an unfamiliar story.

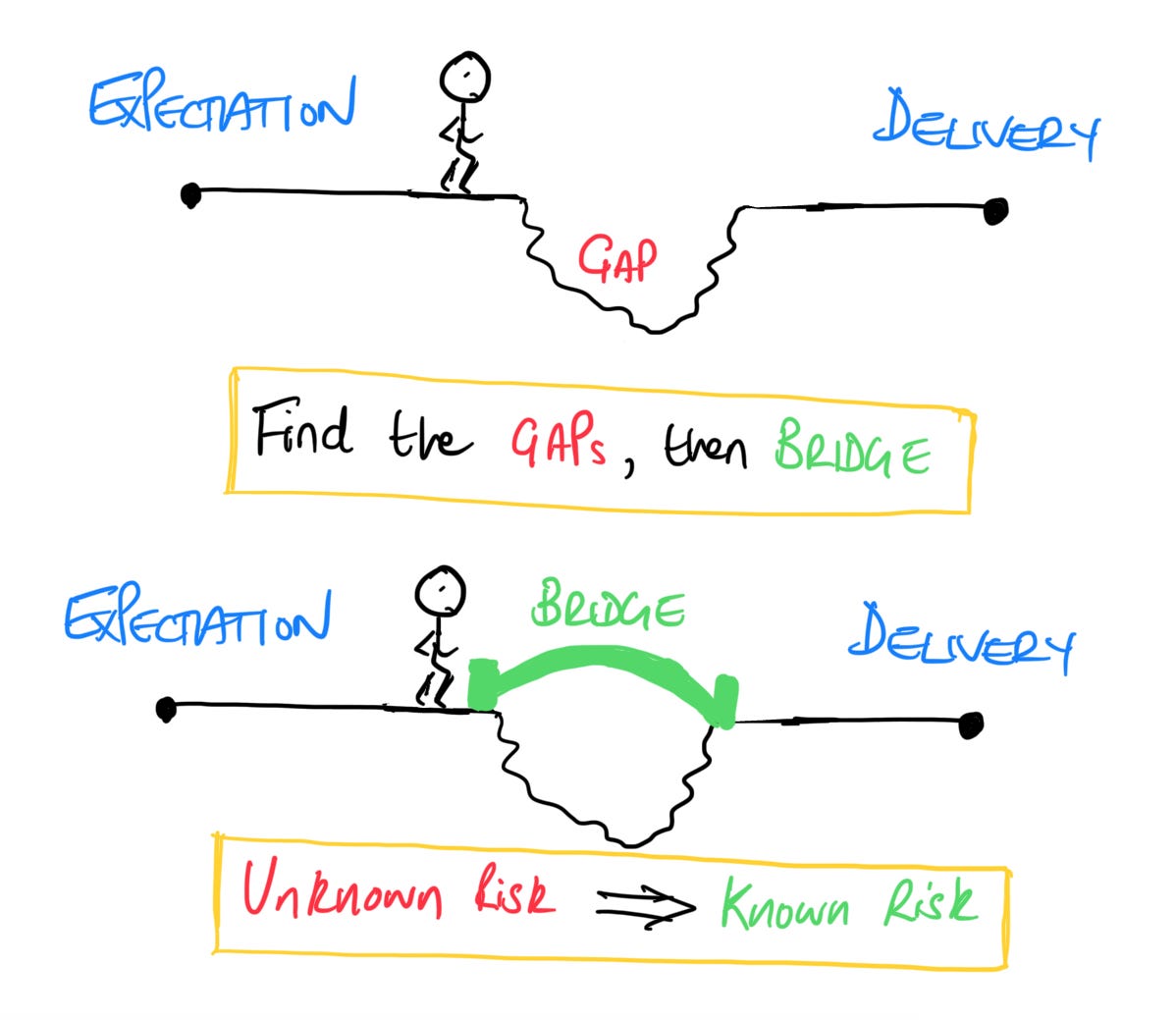

The root cause of your stress? Poor or non-existent Capability and Capacity assessment and requirements follow-up - resulting in bad assumptions.

Goal

My goal here is to build your understanding and help you to check the capability and capacity of a team to deliver its products and services in line with the information requirements and standards required. Giving you the opportunity to mitigate any gaps, increasing certainty in the price offered for goods and services, correcting bad assumptions.

Basics

You wouldn’t employ a joiner, if you weren’t sure they could competently work with timber. You wouldn’t employ a design consultant if they didn’t hold the required accreditations or insurances. We routinely check financial stability, safety records, and sustainability policies. But we rarely check our suppliers can produce the information we need in the way that we need it.

Capability and Capacity Assessment is crucial for procuring information effectively. For those managing the project operationally and commercially this process ensures that all parties involved can meet the project’s information requirements - removing any unknowns and clarifying any assumptions.

Though the need to do this is just common sense, this process is a required part of ISO19650-2. Read more about this standard at the UK BIM Framework website.

Gaps

What you’re looking for are gaps. Gaps in capability and capacity of your own team, and your suppliers, to meet the information requirements. These gaps could be:

Capability

Technology: they don’t have access to the software to produce the information as per the standard required.

Competence: they don’t have the training or experience to produce the information as per the standard required.

Capacity

Resource: they don’t have enough capable people to produce the information on time, to the required standard

Money: their price doesn’t include for the resources required to produce the information on time, to the required standard

Cost

If our information requirements and standards are as lean as they should be, then they are the bare minimum to suit the use cases of both the end-user of the asset and the team delivering the project. This being true, any shortfall in the information produced impacts the bottom line, the gap must be bridged.

When selecting suppliers to work on our project cost is a significant part of the decision - rightly so. However, filling in shortfalls in capacity or capability will cost you time and money. Therefore, we must be able to look at perspective supply chain equally - apples vs apples. It’s important to assess their ability to deliver requirements at the enquiry stage. By understanding if they can meet the standards, we better understand where the price sits compared to their competitors.

An example:

Supplier A can’t meet the information requirements as they don’t have the required modelling capability, their price is £200k for the work. We know that to bridge their gap in modelling capability we will need to engage an agency, costing us about £50k, giving use a total cost of £250k.

Supplier B has the in-house modelling capability and can meet our needs, their price is £230k.

Without checking capability and capacity to meet our information requirements we may have simply went for the £200k quote (all other things being equal), leaving you with a £50k issue to manage.

How to do it

Hopefully you now see the impact of not knowing where your capability and capacity gaps are? If not please reach out and I’d be more than happy to talk it through with you.

So, how do you build this into your procurement processes?

This bit gets a little bit technical, so, if you don’t need the detail feel free to head to the next section where you’ll find some helpful tips.

Understand and/or Establish Information Requirements, Standards, and Procedures

Understand the clients requirements, such as:

The Exchange Information Requirements (EIR): Defines what information is needed, when, by who, and the Level of Information Need.

Information Standard: Defines the format and structure of identified information

Information Production Methods and Procedures: Defines any specific process to produce the information and exchange it.

Reference Material and Shared Resources: can include templates, base maps, guidance materials and more to be used

Works Information: There may be information requirements or standards in this pack not covered in other documents, especially in the absence of those documents.

Understand Delivery Team Requirements, such as:

Planning: What information do you required to carry out planning. For example, what information should be included in a programme submission and in what format?

Design: What information do you need in drawings and models to construct the works - what information, in what format, etc… For example, materials specified in the model in a specific field at Technical Design stage.

Reporting: What reporting do you need to do and what information do you need from teams to complete it. For example, you need weekly productivity updates from each discipline.

Engineering/Surveying/Site Capture…

Social and Environmental Considerations…

And more…

Consolidate needs from the client and the delivery team into a single set of requirements, standards, and procedures. To make it easier for everyone to understand tabulate requirements and allow them to be filtered by supplier or discipline. Make these documents as light as possible. Everything for a reason.

Assess Internal Team Capability and Capacity:

Don’t forget your own team. Evaluate whether your team has the necessary skills and resources.

Two-Step Assessment of the Supply Chain:

Initial Enquiry: Use simple forms and existing procurement tools to gauge interest and capability.

In-depth Assessment: Conduct thorough evaluations before contract signing. This should feel like an audit, going over their team organogram, previous experience, certifications, etc…

Incorporate requirements, standards, and procedures into Contracts:

Ensure all agreed-upon requirements are bound into the contracts clearly.

Manage change - some needs will change for good reason, ensure this is proactively managed with the supplier.

Monitor Compliance and Performance:

Keep detailed records of performance and compliance to inform future appointments.

Keep a database of assessments and performance:

At company level it would be wise to keep a central database to track assessments and performance over time. This will reduce time and effort for any subsequent projects and appointments.

Tips

Thanks for taking the time to read this article. We’ve established that a little effort early on can mitigate significant risk later using Capability and Capacity Assessments.

If you have any thoughts on any of what I’ve covered, if you disagree with anything, please leave a message in the comments.

I’ll leave you with these tips on getting the most of of your Capability and Capacity Assessments:

Understand that you are procuring information: Recognise that accurate information is as vital as the physical services or items being procured.

Information has Value: Understand that information has value. Use it, and protect it.

Know your Information Needs: Clearly define essential information needs to make the project flow. Don’t go overboard and create waste.

Get contractually secure: Ensure all necessary information requirements are legally embedded in appointments, contracts, and agreements.

The right checks…: Check for necessary accreditations, past experience, internal processes, and skills. Be sure not to simply accept company level assessments, you want to know about the resources which are going to be delivering on your project.

Carried out in a timely fashion: Conduct assessments early in the selection process to inform decisions.

Price the Gaps: Account for any gaps detected. Ensure this is considered when reviewing prices between competitors. Apples for apples.

Engage with Teams: Supplement desktop studies with direct interactions. Such as meeting the team at their own office, reviewing previous work together, etc…

Maintain an actionable database: Use digital tools to store and share performance data.

Track Performance and Compliance: Use lessons learned to improve future projects.